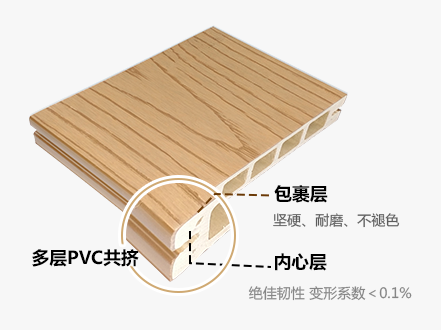

High-end outdoor "BettoWood", capped by the super high weatherability material, master the core technology of "double-layer co-extrusion" & "three layers co-extrusion, which take the lead in physical and chemical performance of composite material.

BettoWood have strong weatheribility, high flame retardant, superior heat stability, excellent surface hardness: PVC coextrusion products passed 1000 hours of exposed to xenon lamp test by SGS, while ASA co-extrusion products passed 6000 hours, both still reach the grey scale is 4-5. Flame retardant scale is Bf1-S1. Surface hardness>= 82 HDB, Shrinkage rate is limited within 0.1%. The above indicators ensure BettoWood a pioneer in the composite industry.

BettoWood is the first company to break through co-extrusion technology and master "double-layer co-extrusion" & "three layers co-extrusion of composite in China.

BettoWood master core technology of co-extrusion, maturely change different co-extrusion: PVC co-extrusion & ASA co-extrusion, which can meet various demands of clients.

BettoWood has been awarded the certificate of Invention & Creation of "a super weather resistant PVC co-extrusion layer material and its manufacturing method", and has numbers of patents, including Utility Patents, Design Patents, Structure Patents.

BettoWood become a main drafting unit of The New Standard of National Composite Industry and National Composite Green Standard.

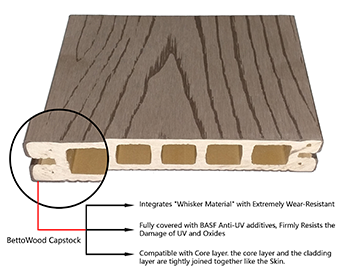

BettoWood are protected inside and outside. The core is tough and the capstock is hard and wearproof. So that the performance of composite can get all-round enhancement.

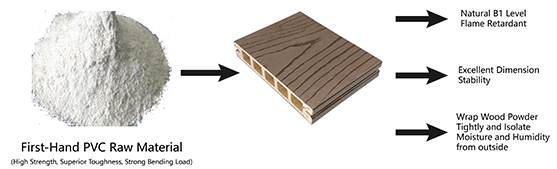

Duly best wood core layer using imported new PVC plastic raw materials, to join the very fine wood powder, the research and development of wood unique formula, use wood powder of nanoscale particles of the modified PVC plastic tightly wrapped in new, fine wood powder with the perfect fusion of PVC resin, completely cut off from the source wood powder contact with moisture, moisture, to avoid deformation and buckling problems of wood fibers swell caused.Experimental data showed that the water absorption rate of BettoWood was far less than 0.1%, with almost no water absorption.

The physical properties of first-hand PVC is supier: High strength, superior toughness, strong bending load

PVC is natural flame retardant. Its’s scale is B1 level without adding any additives

PVC has excellent dimension stability when occurs heat shocks. Modified with Betto formula, shrinking rate can limit within 0.1% under the temperature from -40 ℃ to 70 ℃.

PVC is polar plastic, can be perfectly integrated with wood powder. Wrap the wood powder tightly and Isolate the moisture and humidity from outsid.

The core of BettoWood adds with fine wood powder, and select the first-hand PVC compatible with wood powder. So that it becomes the reinforced polyester fiber material, which greatly improves the tensile strength, tear resistance and bending strength performance.

Integrates "whisker material" with extremely wear-resistant into overcoating layer to ensure BettoWood has ultra-strong wear resistance. Although it’s very thin, the performance is superior.

BettoWood capstock is fully covered with the expensive imported BASF anti-UV additives, which firmly resists the damage of ultraviolet rays and oxides to the product. Use ultra-high weather resistance capstock formula to achieve all-weather performance.

BettoWood capstock is compatible with the core layer. In the high-temperature mold, the core layer and the cladding layer are tightly joined together, just like skin, will not take off.

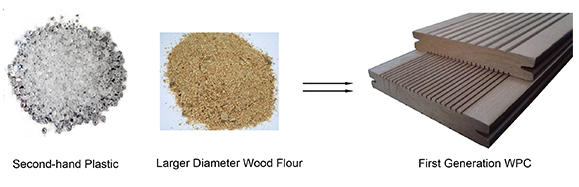

30% second-hand plastic+ 60% larger diameter wood flour or even wood chips + 10% additives.

Plastic:First-generation composite based on HDPE, PP and PS plastics as raw material, which has been several round recycled. The components of these plastics are complex and most of properties such as toughness, strength and bearing capacity have been lost.

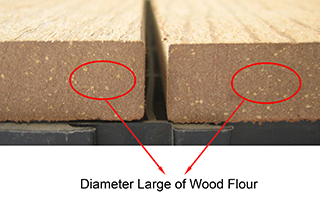

Wood Flour:First-generation composite used larger diameter wood flour or even wood chips as raw material. These Rough wood flour directly exposed to outdoor conditions.

Flame retardant:PE, PP and PS plastics are all non-flame retardant plastics, so is the first-generation composite.

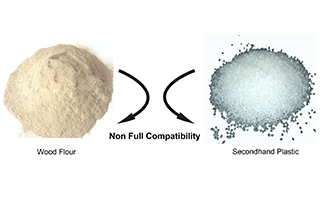

Compatibility:PE, PP and PS plastics are non-polar, but wood powder is strongly polar. Therefore, in the process of mixed preparation, there is a high interface energy difference between plastic and wood powder. Plastic and wood powder are difficult to achieve full compatibility, could not make plastic has the rigidity and strength of wood powder. The mechanical performance of a generation of plastic wood is very poor.

Non-capped:First generation composite directly exposed in the UV, humid air, easy to absorb water expansion, resulting in cracking, deformation, warping, even moldy.

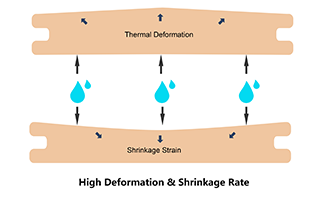

Dimensional Stability:PE, PP, PS plastic stability is poor, deformation and shrinkage rate is high, almost around 2%-5%.

The following real case effect display effect

The following real case effect display effect

The following real case effect display effect

The following real case effect display effect

The following real case effect display effect

Components:First Generation (core layer) + HDPE Plastic (cap layer) Classification:Due to the capped degree of outer protective layer, it can be divided into half capped and full capped

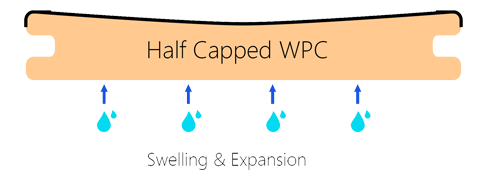

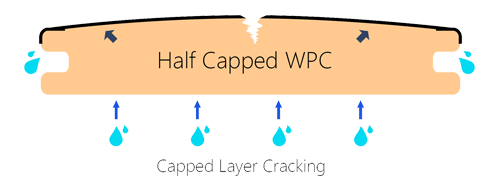

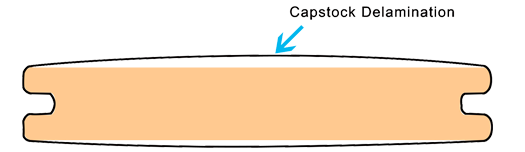

Half Capped Composite Wood indeed UV-resistance to some extent, however the capped layer and underside is not the same material. Their shrinkage rate and water absorption rate are different. So new problems occur.

The capped layer is the plastic with extremely low water absorption rate, while the core layer is still first-generation composite with high water absorption rate due to wood flour exposed to elements. When water is continuously drawn from the bottom and the grooves, the underside is water swelling. however,the groove is fixed on the joist. Therefore underside and groove is not uniform that create both ends warping.

Core layer continuously absorb water that makes composite swelling. Accumulate to a certain extent, the force will lead crack in the capped layer.

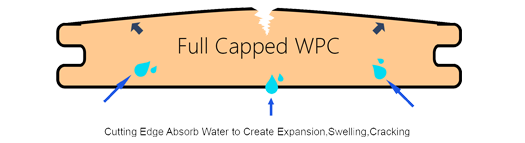

1)Full capped composite wood protected by all around, but the cutting end of the sheet inevitably being exposed in the moisture condition. It still absorbs water that create expansion and warping deformation.

2)Full capped composite wood enhances wear-resistance, impact shock performance, but it still uses several round recycled plastics. These can not solve poor dimensional stability and short of strength problems.

3)Full capped composite wood couldn’t reach flame retardant standard using in public places or exterior wall decorations, unless add double costs.

4)the capped layer and the core layer often bond insufficient, easily occur capped layer and core layer separate.

Contact : Mr. Xu

Mobile: 0086 13412639960

E-mail: yingxu@bettowoodwpc.com

Fax:0086 0769 84429098

Address:Building 10, No.6 Heshi Road, Shishuikou Village, Qiaotou Town, Dongguan, Guangdong,China

WeChat consulting

Ali shop